What is a Superheater? Why is it used in the boiler?

A superheater is a set of parallel tubes connected between the two headers to minimize the pressure drop. The purpose of a superheater in the boiler is to raise the temperature of the saturated steam. And to absorb all the water and moisture content present in the saturated steam. One header of the superheater is connected to the steam drum to receive saturated steam and another header of the superheater is connected to the outgoing pipe followed by the main steam stop valve (MSSV). In some boilers, the superheater tubes are arranged vertically and horizontally. In a vertical superheater, the condensate cannot be drained out completely, when the boiler is in shut-off condition. This type of superheater is called a non-drainable superheater, and the vent of this superheater is kept open during start-up so that the condensate can evaporate easily. In a horizontal superheater, the tubes are arranged on a slope so that the condensate can be drained out easily. This type of superheater is called a drainable superheater.

Why is superheated steam temperature controlled?

The superheated steam temperature of the boiler is required to maintain within the limit. The main steam temperature must be equal to the set point or the design temperature. To drive the steam turbine, the superheated steam temperature must be equal to the rated design value. And to minimize thermal stress, the temperature must be maintained within its limits. When steam demand drops, the steam temperature increases, and flow in the superheater reduces. When steam demand rises, the flow in the superheater increases, and steam temperature decreases.

What methods are adopted to control the temperature of the superheated steam?

To control the temperature of the superheated steam the following methods are adopted.

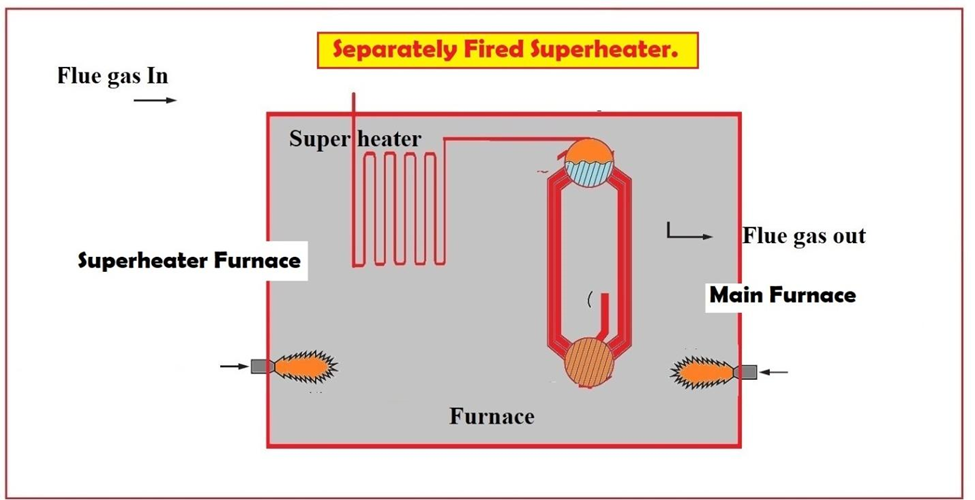

Separately –Fired Superheater Method:

Separately Fired Superheater

In this method, there are two superheaters and two furnaces. The radiant superheater is placed in another furnace and the convective superheater is placed in between the common flue gas path of both furnaces, i.e. in between the main boiler furnace and superheater furnace, the rise in superheated steam temperature depends upon the firing rate in the furnace.

Excess Air Control Method:

This is done by controlling the mechanical draught systems. The air supply to the furnace can be varied accordingly to control the temperature of the superheated steam. To increase the superheated steam temperature the air supply must be increased. The flue gas temperature is raised by supplying excess air through mechanical draught systems and the heat absorption rate of the furnace water wall is reduced. If excess air is supplied more heat transfer takes place at the superheater tube and the steam temperature increases. If the combustion air is reduced the steam temperature decreases and heat absorption at the water wall increases. Heat contents in the flue gas decrease and the heat transfer to the superheater decreases as well. This type of control is mostly used where a convective superheater is used.

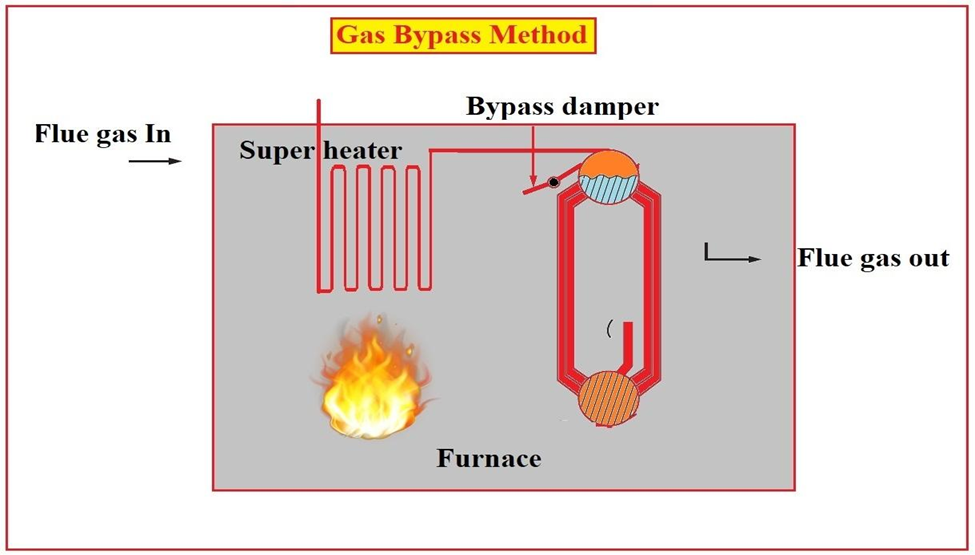

Gas Bypass Method:

In this method, the damper is used to bypass the flue gas path so that some quantity of flue gas does not flow through the superheater. During low load when the steam flow is less in the superheater, the bypass damper is kept open. Some quantity of flue gas is bypassed. As less volume of hot flue gas flows through the superheater, the temperature of steam can be maintained constant during lower load conditions. During higher load, the damper is closed and the entire flue gas is allowed to flow through the superheater.

According to the desired temperature at a certain load, the damper is set at a certain position.

The damper has to operate at a high temperature and in an erosive environment. The draft loss in the flue gas path varies periodically.

The draft loss is more when the damper is closed so that flue gas flows through the superheater.

The draft loss is less when the damper is opened so that the flue gas path is bypassed.

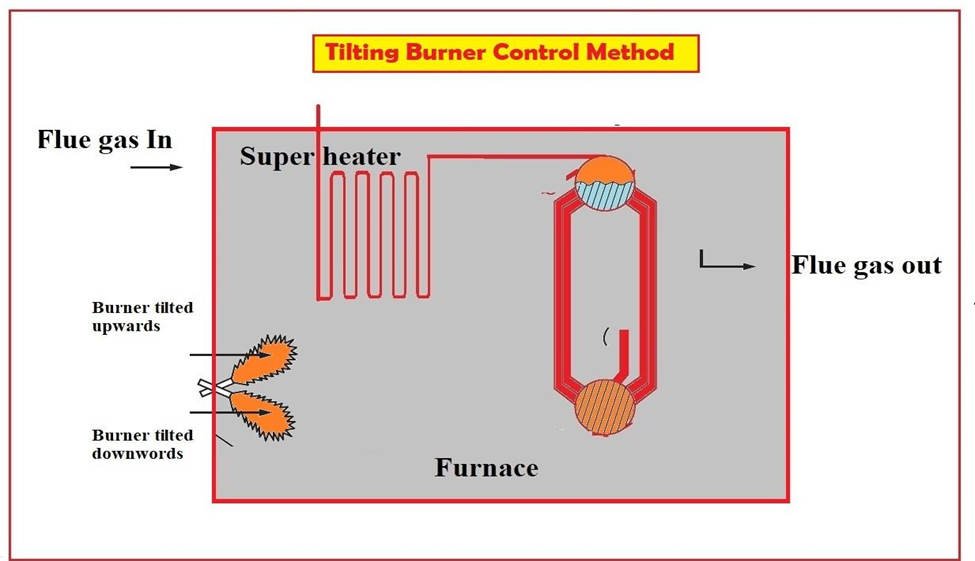

Tilting or Adjustable Burner Control:

Tilting Burner Control Method

In this case, the burner is tilted or adjusted to control the superheated steam temperature. And the burners are designed in such a way that they can be tilted upward or downward.

Depending upon the requirement, the burner may be tilted upward or downward

When the burner is tilted downward, the flue gas temperature towards the superheater zone is reduced and the temperature of the water wall is raised.

When the burner is tilted upward, the flue gas temperature towards the superheater zone is raised and the temperature of the water wall is reduced.

In some boilers, burners are fixed at different elevations of the furnace.

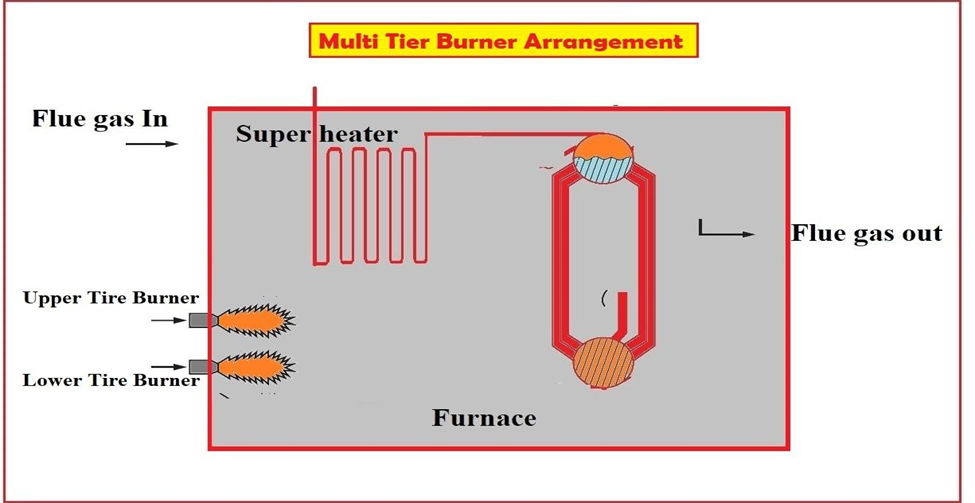

Multi Tier Burner Arrangement

During low load, the upper tire burners are taken into service. So that the flue gas temperature at the furnace exit side (superheater inlet), and the steam temperature increase.

During higher load, both the lower tire burners and upper tire burners are used so that the furnace exit temperature is maintained constant.

Flue Gas Recirculation Method:

To control the superheated steam temperature, the flue gas exhausted from the economizer is circulated back to the boiler furnace with the help of a mechanical draught system.

If more gas is recirculated, the superheated steam temperature will increase. Heat absorption at the water wall will decrease.

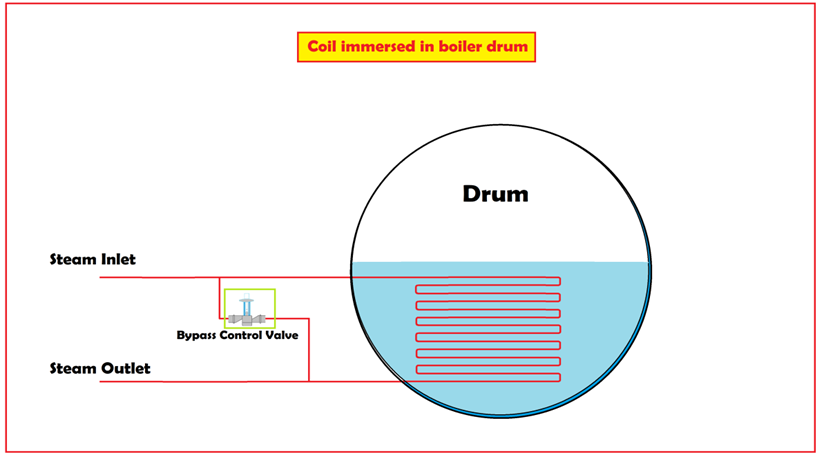

Coil Immersion in Boiler Drum:

Coil Immersed In Boiler Drum

In this method, some part of the superheated steam is passed through the boiler drum by immersing a coil in it. And the bypass valve is provided to control the flow of steam to the drum.

If the superheated steam temperature rises. The superheated steam is passed through the coil immersed in the boiler drum and the temperature of the steam is controlled. During this time the bypass valve must be closed.

When the superheated steam temperature decreases, the bypass control valve is opened. And most of the steam is passed through the bypass line and now the superheated steam temperature is increased.

Desuperheating or Attemperation Method:

This is the most common method to control the temperature of the superheated steam. In this method, the condensate (normally boiler feedwater) is sprayed directly into the superheated steam. Sometimes superheated steam is cooled in a heat exchanger where the steam flows in the coil and feedwater flows in the shell. Both these methods are very effective.

The three superheaters called a primary superheater, intermediate superheater and secondary superheater are used to control the temperature of the superheated steam, and the two attemperators are installed between these superheaters. One is between primary and intermediate and the other is between intermediate and secondary superheater.

As the superheated steam passes through the secondary superheater the moisture in the steam is easily eliminated.

There are two types of desuperheating methods.

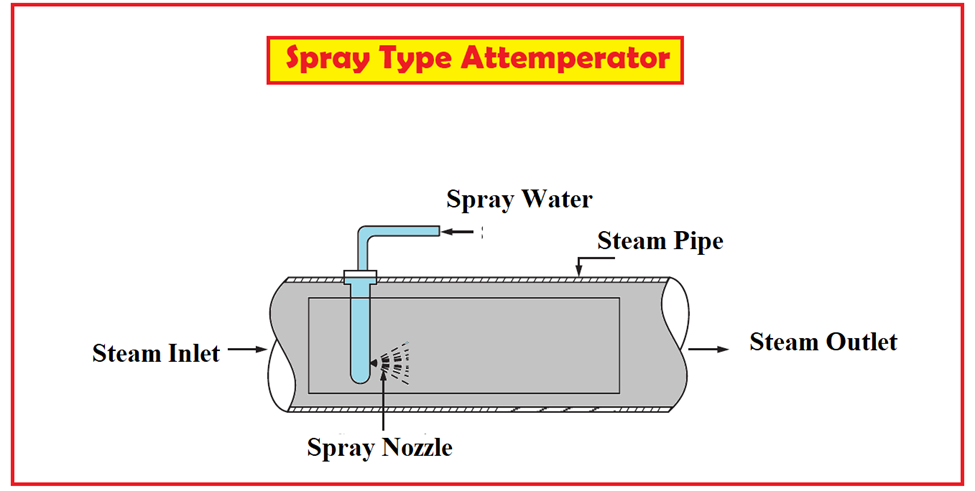

Spray Type Attemperator:

Spray Type Attemperator

In a spray-type attemperator, the spray nozzle is fixed to the steam header with a suitable pipe connection.

It is the most common type of desuperheater where the atomized spray water is sprayed directly to the superheated steam through a set of nozzles.

If the outlet temperature of the intermediate superheater is high then the control valve allows more spray water through the nozzle to reduce the temperature to the set point.

The temperature control loop is set in such a way that the spray water quantity can be adjusted automatically

The spray water evaporates completely at the end. So that there is no chance of rust or corrosion to the steam turbine blades.

Surface Type Attemperator:

Here the feedwater doesn’t come in contact with the superheated steam. And the superheated steam temperature is controlled by varying the feedwater flow in a heat exchanger.

Feedwater flows in the calendria of the heat exchanger and the superheated steam flows inside the tube. To control the temperature of the superheated steam the excess water is allowed to flow. If not the feed water is bypassed with the help of the control valve.

The advantage of a surface-type attemperator is the steam doesn’t come in contact with water.

What material is used in making superheater tubes?

The superheater is subjected to high temperatures. So, a special alloy of steel is used in making the superheater tube because the alloy steel is high heat resistant and non-corrosive. The superheater tube is alloyed with chromium, molybdenum, nickel, titanium, and niobium.

How are the superheaters in the boilers classified?

The super-heater in the boiler is classified based on the heat transfer mode

Convective Superheater

This superheater is placed in the convection zone of the boiler. Heat is transferred by the convective method.

Radiant Superheater

This type of superheater is located in the radiation zone of the boiler. Superheater tubes are exposed to the flame of the furnace.

Platen Superheater

This type of superheater is located in between the radiation and convection zone of the boiler.

Post time: May-31-2022